INTRODUCTION

As urban areas continually expand, a large percentage of high volume, high speed roadways are located within metropolitan areas, resulting in a great number of people being exposed to high levels of roadway noise. Controlling this noise is often a required part of highway construction or suburban expansion. Although the perception of unwanted sound varies from individual to individual and from one activity to another, objective criteria have been established to help designers determine when noise abatement is required, and the levels of noise reduction that will relieve the problem.

Noise abatement measures should be individually evaluated for each project, based on the project’s noise reduction goal and budget, the community needs, and longer-term maintenance and durability issues. Alternatives for reducing traffic noise include:

- land use planning: separating noise-sensitive uses from highways,

- controlling noise at the source: such as by reducing speed limits or prohibiting truck traffic, and

- attenuating noise by modifying the horizontal or vertical alignment of the highway, using larger right-of-ways, or shielding the noise with a barrier.

Sound barriers are solid obstructions built between the noise source and the receiver – they are often chosen as the most expedient and effective method to reduce highway traffic noise. Although earth berms can act as sound barriers, solid walls are more often used. An effective barrier can significantly reduce the level of unwanted noise, while providing an attractive durable element in the community.

Concrete masonry construction successfully fills all of the requirements for effective sound barrier walls, providing excellent noise insulation and a wide choice of aesthetic styles, excellent stability, strength, durability, and low maintenance. These benefits are well recognized; concrete masonry sound barriers represent over five times the wall area than the next popular choice, wood post and plank (ref. 4).

This TEK covers acoustic requirements for concrete masonry highway sound barriers. For structural design considerations, the reader is referred to Allowable Stress Design of Pier and Panel Highway Sound Barrier Walls (refs. 3).

NOISE REDUCTION REQUIREMENTS

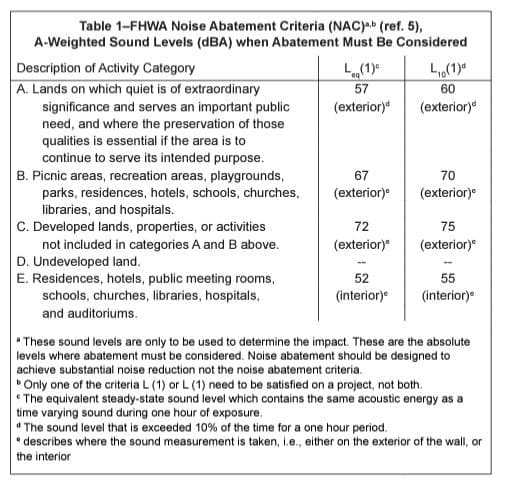

The Federal Highway Administration (FHWA) publishes two criteria for determining when highway noise abatement is required. Values are expressed in dBA which is defined as a time weighted average sound level when measured on the A-scale of a standard sound meter at slow response. The two criteria are:

- when predicted noise levels exceed FHWA’s noise abatement criteria (see Table 1), or

- when predicted noise levels represent a substantial increase over existing noise levels.

The term “substantial increase” is defined by state highway agencies, but is most often taken as a 10 to 15 dBA increase in noise levels (ref. 2). Once either one of these criteria triggers the need for abatement considerations, the designer is required to provide a substantial reduction in noise levels, typically defined as a 5 to 10 dBA reduction (a 10 dBA reduction will generally be perceived as halving the noise; a reduction less than 5 dBA would probably not be noticeable).

The noise abatement criteria (NAC) in Table 1 are not meant as a design goal nor to represent desirable noise levels. If predicted levels exceed the NAC, abatement measures must be taken to reduce the predicted level by 5 to 10 dBA, not just to the level indicated in Table 1. Likewise, if predicted noise levels are 15 dBA above current levels, noise abatement must be considered even if the predicted level is below the NAC.

BARRIERS FOR NOISE REDUCTION

Total noise reduction by a barrier is commonly referred to as insertion loss. Simply defined, insertion loss is the difference in sound level before and after a barrier is placed next to a highway.

Insertion loss has five components:

- barrier attenuation due to the diffraction of sound waves over and around a barrier placed in the line-of- sight between the source and receiver,

- transmission loss of sound through the barrier,

- reductions in barrier attenuation resulting from multiple reflections caused by double barriers,

- shielding attenuation from other barriers between the source and the receiver, and

- loss of excess attenuation already received from soft ground cover.

For most highway applications, the first two of these components are by far the most significant.

Barrier Attenuation

Barrier attenuation due to sound wave diffraction is controlled by designing the barrier to be both tall enough and long enough to adequately shield the receiver. The noise barrier should be tall enough to break the line of sight between the highway and the receiver – noise barriers adjacent to the highway do very little for homes on a hillside overlooking that highway. Sound travelling around the ends of sound barriers can degrade the barrier performance. To avoid these end effects, one rule of thumb is to extend the barrier four times as far in each direction as the distance from the receiver to the barrier. If this is not possible, the sound barrier can often be combined with the natural terrain, such as knolls. Another alternative is to provide returns on the ends of the barrier back towards the community to reduce the noise level near the end of the barrier.

Barrier Physical Characteristics

Transmission loss through the barrier is controlled by the barrier material (see next section) and by eliminating holes and other openings in the barrier. FHWA and the American Association of State Highway and Transportation Officials (AASHTO) both recommend that the transmission loss be at least 10 dBA above the attenuation resulting from diffraction over the top of the barrier (refs. 1, 2).

Barrier insertion loss can be compromised if there are holes or openings in the barrier. For large openings, sound energy incident on the barrier will be directly transmitted through the opening to the receiver. When the opening is small, an additional phenomenon occurs: upon striking the barrier wall, the sound pressure can increase, effectively amplifying the transmitted sound. Maintenance openings and doorways can be placed behind a baffle or recessed wall area to minimize the effect of the opening. When sound walls terminate at an earth berm, care should be taken to ensure that there are no gaps between the wall and berm.

Barrier location also impacts effectiveness. For a given barrier height, moving the wall closer to the receiver, or closer to the source, will provide additional noise reduction (ref. 1). Barriers placed on hilly terrain above the highway can typically be shorter and still provide the same noise reduction as a taller barrier placed closer to the highway. Changes in wall height impact the barrier’s acoustic performance. Abrupt height changes of 2 ft (0.61 m) or more can significantly reduce effectiveness. A better alternative is to gradually step the height down to the lower level. This is particularly easy to accomplish with concrete masonry, as the modular size facilitates such changes.

Barrier Reflection

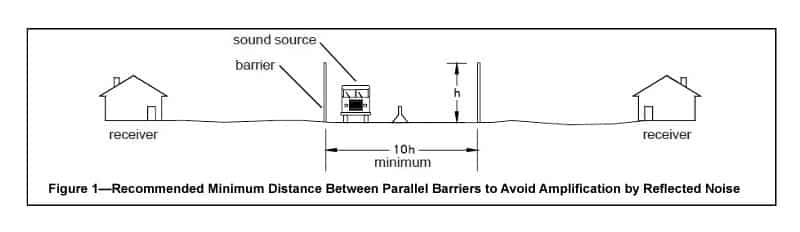

Recent research has clarified the impact of acoustic reflections, particularly between two parallel barriers, and in the case where a barrier is placed on only one side of the highway. In theory, multiple noise reflections between two parallel walls can reduce the effectiveness of the individual barriers and contribute to overall noise levels. To avoid reducing the performance of parallel barriers, it is suggested that the ratio of the distance between barriers to the average height of barrier above the roadway be at least 10:1 (see Figure 1). In these cases, measured increases in noise levels due to reflected noise have been below the threshold of normal human hearing (ref. 1).

Similarly, when a barrier is constructed on only one side of the highway, highway noise levels on the opposite side of the highway are not significantly affected. Measurements made to try to quantify the increase in noise level have shown maximum increases of 1 to 2 dBA, an increase not detectable to the average human ear (ref. 2).

Barrier Types

Many types of materials are used to construct highway noise barriers. For maximum performance, however, the material should be rigid and of sufficient density to provide a transmission loss of 10 dBA greater than the expected reduction in noise due to diffraction over the top of the barrier alone (ref. 2). The preferred method of rating a material’s ability to transmit noise is by the transmission loss (TL), which is related to the ratio of incident acoustical energy to transmitted acoustical energy. For highway noise sources and their typical sound spectral content, the transmission loss of common barrier materials increases with increasing surface weight of the material.

For many common heavyweight materials used in barrier construction, such as concrete masonry, transmission loss values are usually more than adequate. For less massive materials, such as steel, aluminum, and wood, transmission loss values may not be adequate, especially where large insertion losses are required. Typical TL values for common materials are given in Table 2.

Under certain conditions, vegetation can provide sound attenuation. AASHTO suggests that vegetation at least 15 ft (4.5 m) tall, and 98 ft (30 m) deep with sufficient density to completely block the line of sight can achieve a noise reduction of up to approximately 5 dBA (ref. 1). However, since it is usually impossible to plant enough vegetation to achieve a substantial noise reduction, the FHWA does not consider vegetation to be a noise abatement measure (ref. 2). Vegetation can, however, provide visual interest and relief, thus providing a psychological benefit, if not an acoustic one.

REFERENCES

- Guide on Evaluation and Abatement of Traffic Noise 1993. American Association of State Highway and Transportation Officials, 1993.

- Highway Traffic Noise Analysis and Abatement: Policy and Guidance. Federal Highway Administration, Washington, D.C., 1995.

- Allowable Stress Design of Pier and Panel Highway Sound Barrier Walls. TEK 14-15B, Concrete Masonry & Hardscapes Association, 2004.

- Highway Traffic Noise in the United States: Problems and Response. Federal Highway Administration, Washington, D.C., 1997.

- Procedures for Abatement of Highway Traffic Noise and Construction Noise. Code of Federal Regulations, 23CFR Part 772, U. S. Government Printing Office, 1997.

- Noise Barrier Design Handbook, FHWA-RD-76-58. Federal Highway Administration, Washington, D.C., 1976.

TEK 13-03A, Revised 1999. CMHA and the companies disseminating this technical information disclaim any and all responsibility and liability for the accuracy and the application of the information contained in this publication.