INTRODUCTION

Concrete masonry is widely specified for fire walls and fire barriers because it is noncombustible, durable and economical. Although these constructions are ideally continuous, various conditions require joints or penetrations in fire walls and fire and/or smoke barriers, including movement joints, pipe or cable penetrations and electrical wiring and outlets. Regardless of the type of penetrating item, gap or joint, the International Building Code (IBC) (ref. 1) requires that the continuity of the fire-resistant or smoke-resistant assembly be maintained.

A through-penetration firestop system is an assemblage of specific materials or products designed, tested and rated to resist fire spread for a prescribed period of time through openings made in fire resistance-rated walls, floor/ceiling or roof/ceiling assemblies. Firestopping must be installed in accordance with code requirements to maintain fire and life safety.

Choosing an appropriate firestopping system is a key component to a successful installation. The firestop system must be chosen from a building-official-approved listing service. Alternatively, one of the generic listed materials—concrete, mortar or grout—can be used within the limitations of the code.

Various methods are used to maintain continuity where joints, gaps and penetrations exist in fire-resistance-rated masonry construction. For details of control joints for fire-rated concrete masonry construction, refer to the subsequent Joints section and TEK 07-01D, Fire Resistance Ratings of Concrete Masonry Assemblies (ref. 2). Note that materials installed in joints must resist environmental and movement characteristics as specified by the design professional.

MAINTAINING THE CONTINUITY OF THROUGH-PENETRATIONS

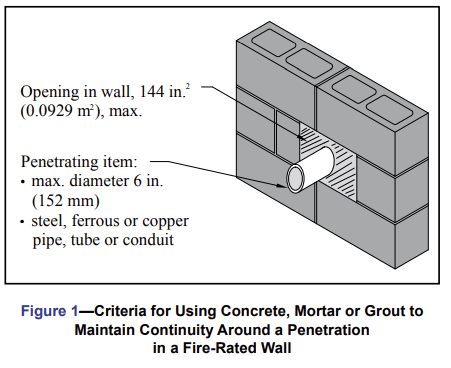

The IBC allows several options for extending the fire resistance rating to protect penetrations through fire walls, fire barriers, smoke barrier walls and fire partitions. Section 713.3 of the 2009 IBC (Section 712.3 the 2006 IBC) contains explicit options permitting the use of concrete, mortar or grout to extend the fire rating through the annular space between the penetrating item and the concrete masonry wall provided the following conditions are met (see also Figure 1):

- the penetrating item(s) must consist of steel, ferrous, or copper pipes, tubes, or conduits;

- the nominal diameter of the penetrating item(s) cannot exceed 6 in. (152 mm);

- the opening through the wall cannot exceed 144 in.2 (0.0929 m2); and

- the concrete, mortar or grout is permitted where it is installed to the full thickness of the wall or the thickness required to maintain the wall’s fire resistance rating (see TEK 07-01D (ref. 2) for concrete thicknesses required to meet various fire resistance ratings). Note that placement around a penetration with masonry usually requires cutting of units. In the case of rectangular penetrations, continuity can be easily maintained by laying units with the uncut web adjacent to the penetrating item and filling the annular space with mortar

In cases where the penetrating item is contained in a sleeve, the annular space includes the space between the penetrating item and the sleeve as well as the space between the sleeve and wall assembly. Although the mason contractor is responsible for mortaring in the sleeve, filling the annular space between the pipe and the sleeve after the pipe is installed is the responsibility of the firestop contractor, piping contractor, or other firm assigned by the prime contractor or building owner/manager.

The design professional is responsible for assigning fire resistance ratings and smoke resistant assemblies, and specifying the test methods for maintaining continuity of the wall, when required. The mason contractor is not responsible for applying firestop material other than mortar, grout or concrete. The mason simply follows the plan sheet for initial construction by laying up the wall around the penetration, or if appropriate, cutting into a constructed wall. When the limitations for using mortar, grout or concrete indicated above are exceeded, then the firestop contractor, piping contractor or other designated party must apply the appropriate firestop.

If one or more of the above conditions for using mortar, grout or concrete are not met, then the firestop system must be tested in accordance with ASTM E814, Standard Test Method for Fire Tests of Penetration Firestop Systems (ref. 3), UL 1479 Fire Tests of Through Penetration Firestops (ref. 4) (with a minimum positive pressure differential of 0.01 in. (2.49 Pa) of water), or an approved assembly tested in accordance with ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials (ref. 5) or a building official-approved alternative per Chapter 1 of the IBC.

ASTM E814 and UL 1479 were developed specifically for through penetrations and cover membrane penetrations as well (see next section, Protecting Membrane Penetrations). Both of these test methods use similar time/temperature curves, and result in a flame rating (F) for the firestop system. The F rating indicates the number of hours the firestop system resisted the passage of fire (during the fire exposure test) or water (during the hose stream test), whichever is lower. The F rating must meet or exceed the required fire resistance rating of the assembly being penetrated.

In addition to the F rating, there are also T (temperature) ratings, L (air, simulating smoke) ratings and, if water resistance is required, W ratings. The T rating indicates the length of time (in hours) it took for the firestop system to heat up on the non-fire exposed side of the assembly to the point where it could cause ignition of combustibles on the unexposed side. This is considered to occur when the temperature on the non-fire-exposed side of the firestop system rises to 325o F (162o C) above the ambient temperature.

It should be noted that in order for a firestop system to obtain a T rating, it must first obtain an F rating. F ratings are required for all firestop systems (except when concrete, mortar or grout are used under the conditions described above), whereas T ratings are not always required.

The L rating is used to maintain the continuity of smoke barriers. UL 1479 is currently the only standard that measures the passage of air through the assembly including the penetrating item, at ambient and at 400o F (204o C). The ambient temperature condition simulates cold smoke, while the 400o F (204o C) condition simulates hot smoke, both measured in cubic feet per minute per square foot of opening area. The lowest L rating is <1 cfm/ft2 (0.005 m3 /s-m2 ). For a penetration assembly in a smoke barrier, the 2006 IBC allows air leakage of 5 cfm/ft2 (0.025 m3 /s-m2 ) of penetration opening at 0.3 in. of water (7.47 Pa) for both the ambient and elevated temperature tests.

PROTECTING MEMBRANE PENETRATIONS

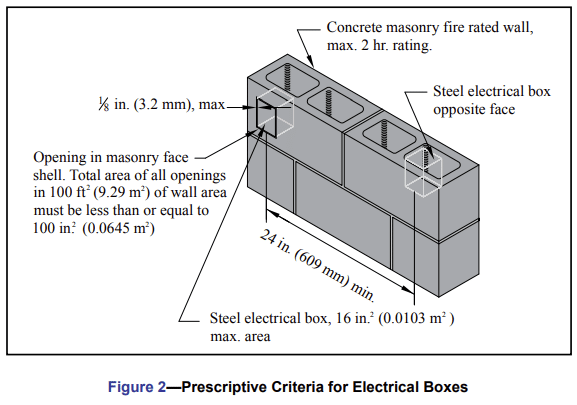

Membrane penetrations, addressed in IBC (2009)section 713.4.1.2, are those which penetrate only a portion of the wall assembly, such as the opening for an electrical outlet. The IBC language for protecting membrane penetrations is very similar to that for through penetrations. However, there are specific prescriptive criteria that address electrical boxes no larger than 16 in.2 (0.0103 m2) in fire walls with a fire resistance rating up to two hours. These criteria address the maximum area of openings, the annular space between the wall and the box, and separation or protection of such boxes when installed on opposite sides of the wall (see Figure 2).

DUCTS

Ducts are addressed in IBC (2009) section 716. Non-dampered ducts that penetrate fire rated walls must comply with the requirements for through penetrations, as described above. Dampered ducts and air transfer openings are tested to either UL 555, Standard for Fire Dampers (ref. 6) or UL 555S, Standard for Smoke Dampers (ref. 7), or both for fire/smoke dampers. Fire and smoke dampers must be tested according to the standards listed above; there are no prescriptive damper treatments that are deemed-to-comply with the IBC.

JOINTS

In Section 714 of the 2009 IBC, any joint in or between fire resistance-rated walls, floor, or floor/ceiling assemblies and roofs or roof/ceiling assemblies is required to provide a fire resistance rating at least equal to that of the wall, floor or roof in or between which it is installed.

The void created at the intersection of an exterior curtain wall assembly and the floor or ceiling assembly must be protected in accordance with IBC Section 714.4.

Fire resistant joint systems must be tested in accordance with the requirements of either ASTM E1966, Standard Test Method for Fire Resistive Joint Systems (ref. 8), or UL 2079, Standard for Tests for Fire Resistance of Building Joint Systems (ref. 9). Control joints not exceeding a maximum width of 0.625 in. (15.9 mm) can be installed if tested to ASTM E119 or UL 263, Standard for Fire Tests of Building Construction and Materials (ref. 10).

Joint systems in smoke barriers must be tested in accordance with the requirements of UL 2079 for air leakage. The air leakage rate of the joint must not exceed 5 cfm per lineal foot of joint (0.00775 m3/s-m) at 0.3 in. of water (7.47 Pa) for both the ambient temperature and elevated temperature tests.

Note that treatments to maintain the fire resistance rating of control joints is also included in ACI 216.1-07/TMS-0216, Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies (ref. 11) which is adopted by reference in IBC Section 721.1. These options are also addressed in TEK 07-01D.

Details of concrete masonry fire wall connections to roofs and floors are shown in TEK 05-08B, Detailing Concrete Masonry Fire Walls (ref. 12).

FIRESTOP MATERIAL AND SYSTEMS SELECTION CONSIDERATIONS

When extending the continuity of the wall to and through the penetrating item or items, the appropriate firestop system (or mortar, grout, or concrete) must be selected. Systems selection is the key to appropriate firestopping. Without proper systems selection and installation, the continuity of the fire resistance rated assembly can be compromised.

Several considerations other than fire and smoke need to be accounted for in selecting the firestop system, regardless of the firestop material or assembly type. For example, how much movement is expected in the joint assembly? The firestop system must match the expected movement of the joint to be able to maintain the rated fire resistance. Similarly, any expected movement of the penetrating item must be accommodated. Locking a pipe into a penetration could interfere with the plumbing or piping system performance.

When choosing materials, it is important to note that copper is not compatible with the cement in concrete and may be compromised over time by the mortar, grout or concrete, if used.

For joint systems, there are many configurations of products that make up the firestop ‘system.’ The system may consist of a mineral wool or other backing, packing or damming material, and one of various sealant types including silicone elastomerics, latex or silicone intumescents, latex, or spray system. Plastic piping, insulations, cable trays, and cable penetrating items may have systems comprised of wrap strips, plastic pipe devices, intumescent blocks, and many other products.

A “systems concept” is critical to extending the fire resistance rating and smoke resistant properties of the wall, for both joints and penetrations. In addition, control joint materials must be compatible with the firestop systems selected if the two intersect. The same applies to fire damper assemblies. This compatibility should be verified with both manufacturers. Most importantly, elastomeric control joint materials must allow for the depth of the completed firestop system in the joint. For penetrations, joints or perimeter fire containment, the firestopping must be installed to the tested and listed system in order to be reliable.

Information regarding the Installation, Inspection and Management of Firestop Systems is available at http://www.fcia. org and contained in the FCIA Firestop Manual of Practice (ref. 13). The FCIA Firestop Manual of Practice is free to architects working for design firms, building officials and fire marshals. CMHA does not endorse firestop contractor certification.

MAINTAINING THE FIRE RESISTANCE RATING

The International Fire Code (ref. 14) makes it clear in Section 703.1 that the required fire resistance rating of all fire-resistance rated construction be maintained through proper repair, restoration or replacement as needed. In addition, as building services change, there may be new penetrations required through fire resistance rated concrete masonry assemblies. These new penetrations must also be protected to maintain the integrity of the construction.

Although not required by current building codes, information for on site inspection of firestop systems is provided in ASTM E2174, Standard Practice for On-Site Inspection of Installed Fire Stops (ref. 15) and ASTM E2393, Standard Practice for On-Site Inspection of Installed Fire Resistive Joint Systems and Perimeter Fire Barriers (ref. 16).

REFERENCES

- International Building Code. International Code Council, 2006 and 2009.

- Fire Resistance Ratings of Concrete Masonry Assemblies, TEK 07-01D. Concrete Masonry & Hardscapes Association, 2018.

- Standard Test Method for Fire Tests of Penetration Firestop Systems, ASTM E814-10. ASTM International, Inc., 2010.

- Fire Tests of Through-Penetration Firestops, UL 1479. Underwriters Laboratories, 2003.

- Standard Test Methods for Fire Tests of Building Construction and Materials, ASTM E119-09c. ASTM International, Inc., 2009.

- Standard for Fire Dampers, UL 555. Underwriters Laboratories, 2006.

- Standard for Smoke Dampers, UL 555S. Underwriters Laboratories, 1999.

- Standard Test Method for Fire-Resistive Joint Systems, ASTM E1966-07. ASTM International, Inc., 2007.

- Standard for Tests for Fire Resistance of Building Joint Systems, UL 2079. Underwriters Laboratories, 2004.

- Standard for Fire Tests of Building Construction and Materials, UL 263. Underwriters Laboratories, 2003.

- Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies, ACI 216.1-07/TMS-0216 07. American Concrete Institute and The Masonry Society, 2007.

- Detailing Concrete Masonry Fire Walls, TEK 05-08B. Concrete Masonry & Hardscapes Association, 2005.

- Firestop Industry Manual of Practice. Firestop Contractors International Association, 2009.

- International Fire Code. International Code Council, 2006 and 2009.

- Standard Practice for On-Site Inspection of Installed Fire Stops, ASTM E2174-09. ASTM International, Inc., 2009.

- Standard Practice for On-Site Inspection of Installed Fire Resistive Joint Systems and Perimeter Fire Barriers, ASTM E2393-10. ASTM International, Inc., 2010.