INTRODUCTION

Heat capacity is a material property used to assess a wall’s thermal mass, and it is often used as a criteria in energy codes and standards. Thermal mass is defined as: the absorption and storage of significant amounts of heat in a building or in walls of a building (ref. 1). Wall thermal mass, such as that present in concrete masonry construction, tends to decrease both heating and cooling loads in a given building, thus saving energy. The amount of savings realized by incorporating thermal mass into a building’s design is a function of several variables. These include local climate, wall heat capacity, fenestration (window) area, fenestration orientation, fenestration solar gain, building occupancy load and other internal gains such as lights and office equipment. The most manageable approach to account for energy savings due to thermal mass is to relate the savings to the wall heat capacity and local climate.

Heat capacity (HC) is defined as the amount of heat necessary to raise the temperature of a given mass one degree (refs. 2, 3), and is calculated as the product of a wall’s mass per unit area by its specific heat.

A building with massive walls, such as concrete masonry, often uses less energy for heating and cooling than does one with lightweight frame walls, wood or steel studs for example. Because of this, the International Energy Conservation Code and ASHRAE Standard 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings (refs. 4, 3), prescribe lower R-value requirements for concrete masonry walls than those for frame walls and metal buildings, in many cases. (This lower required R-value corresponds to a higher required U-factor.) In order to qualify for this lower minimum R-value, ASHRAE Standard 90.1 requires the wall to achieve a minimum HC value. The International Energy Conservation Code defines “mass walls” in terms of wall weight, rather than heat capacity (see reference 5 for detailed information).

This TEK is intended for use by engineers and designers as a guide to determining the heat capacity (HC) of concrete masonry walls.

HEAT CAPACITY VALUES IN CODES AND STANDARDS

ASHRAE Standard 90.1 defines a mass wall as one with a heat capacity exceeding:

- 7 Btu/ft2 °F (45.2 kJ/m2.K), or

- 5 Btu/ft2 °F (32.2 kJ/m2.K) provided that the wall has a material unit weight not greater than 120 lb/ft3 (1,922 kg/m3).

This criteria clarifies that most lightweight concrete masonry

walls are defined as mass walls for the purposes of the

Standard.

Walls meeting either of these criteria are considered mass walls, and are eligible to comply to the Standard using the lower mass wall requirements in the prescriptive compliance tables.

In addition to these prescriptive compliance tables, heat capacity is also used in the ENVSTD compliance software, that forms a part of ASHRAE Standard 90.1, when defining a mass wall assembly. See TEKs 06-12E, Concrete Masonry in the 2012 Edition of the IECC, and 06-04B, Energy Code Compliance Using COMcheck (refs. 5, 6) for further information on energy code compliance options.

Concrete masonry heat capacity values are also required for more rigorous energy analyses, such as those necessary to demonstrate compliance with the Total Building Performance option in the International Energy Conservation Code, demonstrate compliance with the Energy Cost Budget Method in ASHRAE Standard 90.1, or demonstrate energy savings to qualify for LEED® program points.

CALCULATING HEAT CAPACITY

Wall heat capacity is defined as: the sum of the products of the mass of each individual material in the wall per unit area times its individual specific heat (ref. 3). As indicated previously, HC is equal to the mass, or wall weight, multiplied by the specific heat. Therefore, for example, a single wythe concrete masonry wall weighing 34 lb/ft 2 (166 kg/m2) has a HC of 7.14 Btu/ft2 · ºF (1.26 kJ/m2.K), as follows:

This simple calculation is based on a rule-of-thumb that the specific heat of most concretes is very close to 0.21 Btu/lb · ºF (880 J/kg.

K). The actual value depends on the aggregate type used to manufacture the concrete masonry units. Concrete masonry units produced using sand-gravel aggregates tend to have specific heat values of approximately 0.22 Btu/lb · °F (922 J/kg. K), while most other units have a specific heat of 0.20 to 0.21 Btu/lb · ºF (840 to 880 J/kg. K) (ref. 2).

Single Wythe Walls

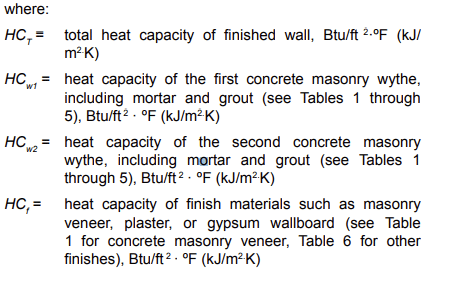

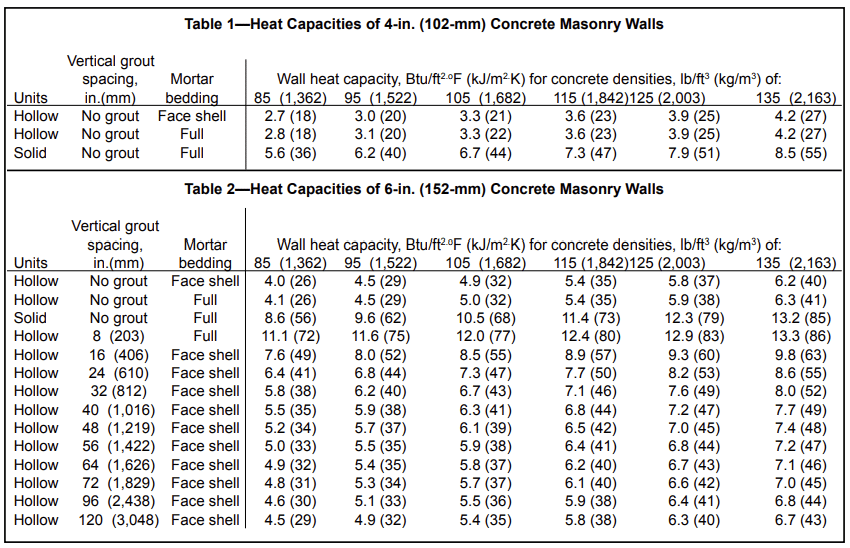

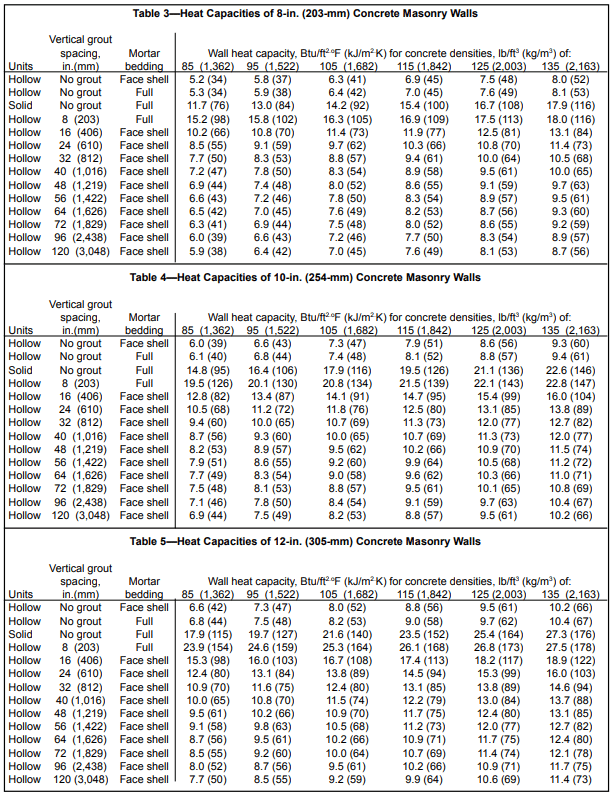

Tables 1 through 5 contain calculated heat capacity values for 4-in. to 12-in. (102- to 305-mm) thick concrete masonry walls. The values are based on: minimum face shell and web thickness requirements of Standard Specification for Loadbearing Concrete Masonry Units, ASTM C-90 (ref. 7); 125 pcf (2,003 kg/m3) mortar; and 140 pcf (2,243 kg/m3) grout. For walls not included in these tables, the heat capacity can be calculated by multiplying the wall weight in lb/ft2 (kg/m2) by the specific heat of 0.21 Btu/lb· ºF (880 J/kg. K). Note that concrete masonry wall weights are tabulated in CMU-TEC-002-23, Weights and Section Properties of Concrete Masonry Assemblies (ref. 8).

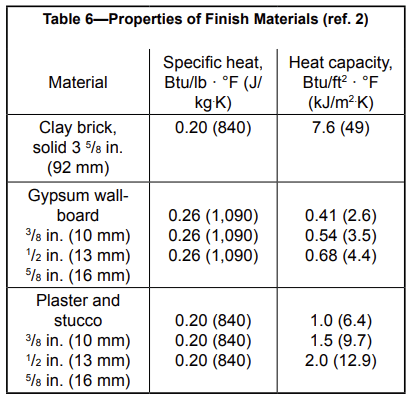

Multiwythe Walls and Finishes

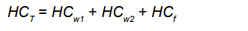

For multiwythe walls or walls including a finish such as gypsum wallboard or plaster, the heat capacity of the second masonry wythe and/or finish is simply added to that of the first masonry wythe, as follows:

REFERENCES

- Guide to Thermal Properties of Concrete and Masonry Systems, ACI 122R-02. American Concrete Institute, 2002.

- 2005 ASHRAE Handbook, Fundamentals, Chapter 23. American Society of Heating, Refrigerating and Air Conditioning Engineers, Inc., 2005.

- Energy Standard for Buildings Except Low-Rise Residential Buildings, ASHRAE 90.1. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2004 & 2007.

- International Energy Conservation Code. International Code Council, 2003 & 2006.

- Concrete Masonry in the 2012 Edition of the IECC, TEK 06-12E, Concrete Masonry & Hardscapes Association, 2012.

- Energy Code Compliance Using COMcheck, TEK 06-04B, Concrete Masonry & Hardscapes Association, 2012.

- Standard Specification for Loadbearing Concrete Masonry Units, ASTM C-90-06b. ASTM International, Inc., 2006.

- Weights and Section Properties of Concrete Masonry Assemblies, CMU-TEC-002-23, Concrete Masonry & Hardscapes Association, 2023.