INTRODUCTION

Sustainable development has been defined as development that meets the needs of the present without compromising the ability of future generations to meet their own needs (ref.1). This is often expressed as a holistic approach to building design, with the goal of optimizing environmental, economic and social impacts, from site selection through building operation and maintenance. A sustainable building optimizes resource management and operational performance, while minimizing risks to human health and the environment. As such, providing a sustainable building project encompasses far-reaching design decisions, and recognizes the interrelationships between virtually all elements and phases of the project.

A range of products and programs has been developed to help designers achieve a more sustainable built environment. Whether in the form of design guidelines for particular building types, or rating systems that step the design team through a series of design considerations, all aim to provide practical guidance for achieving the almost overwhelming goal of sustainability.

Referenced and in some cases mandated by some branches of the Federal government, as well as many state and local governments, the United States Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED®) has become perhaps the most widely used of these programs in recent years. LEED is a voluntary rating system designed to provide guidance as well as national third-party certification for defining what constitutes a “green” building.

Concrete masonry building and hardscape products can make a significant contribution to meeting LEED certification. This contribution is augmented by the recycled content potential of the companion products necessary for a concrete masonry wall, such as grout, mortar and reinforcement products.

Concrete masonry building and hardscape materials can contribute to earning credits in several LEED categories, including Sustainable Sites, Energy and Atmosphere, Materials and Resources and Innovation in Design. More detail on LEED strategies incorporating concrete masonry and hardscape materials is available in TEK 06 09C, Concrete Masonry and Hardscape Products in LEED 2009 and PAV-TEC-016-16, Achieving LEED Credits with Segmental Concrete Pavement (refs. 2, 3).

LEED includes specific rating systems for various applications. The information in this TEK is applicable to LEED for new construction, school, retail, and core and shell development (refs. 4-7).

For these LEED programs, Materials and Resources Credit 4: Recycled Content allows up to two LEED certification points for using materials with recycled content. The inert nature of concrete masonry lends itself well to incorporating recycled materials as cement replacements, as aggregates and as other constituents in the concrete mix. This TEK provides guidance on determining the recycled content of concrete masonry products for the purpose of earning LEED credit under the new construction, school, retail, and core and shell development LEED programs.

The LEED for Homes (ref. 8) recycled content credit differs from these other programs. Concrete masonry walls are eligible for recycled content credit under the LEED for Homes Materials and Resources Credit 2: Environmentally Preferable Products, provided the masonry contains at least 25% recycled content (post-consumer plus one-half pre-consumer, as described in the following sections). Note, however, that the National Association of Home Builders with the International Code Council has developed their own green building standard that has similar requirements (ref. 9). See www.nahbgreen.org for more information.

USE OF RECYCLED MATERIALS IN CONCRETE MASONRY AND HARDSCAPE UNITS

When concrete masonry products incorporate recycled materials, due consideration must be given to ensure that the use of these materials does not adversely affect the quality or safety of the units or construction. Note that some recycled materials may only be regionally available. Designers should work closely with concrete masonry manufacturers to substantiate recycled content.

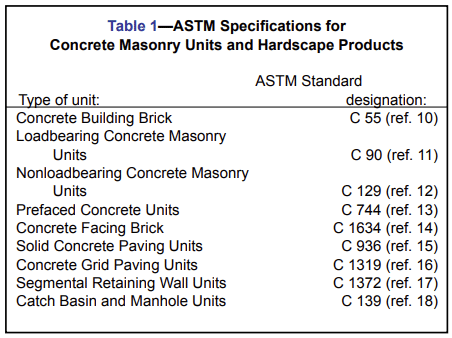

Unit Specifications

Whether produced using recycled or virgin materials, concrete masonry products are required to meet the applicable ASTM unit specification (see Table 1). These standards contain minimum requirements that assure properties necessary for quality performance. For example, many concrete masonry units are required to conform to ASTM C90, Standard Specification for Loadbearing Concrete Masonry Units (ref. 11). ASTM C90 requirements include material requirements for aggregates, cementitious materials, and other constituent materials, physical requirements, finish and appearance requirements, and permissible variations in dimensions.

Aggregates, including recycled aggregates, for concrete masonry units are required to meet ASTM C33, Standard Specification for Concrete Aggregates, or C331, Standard Specification for Lightweight Aggregates for Concrete Masonry Units (refs. 19, 20), except that grading requirements do not have to be met. Aggregate characteristics governed include limits on deleterious substances and aggregate soundness.

Cements are required to meet ASTM C150 and supplemental cementitious materials such as fly ash must meet ASTM C618 (refs. 27, 28). In addition to cementitious materials and aggregates, the ASTM unit specifications also allow for the inclusion of “Other Constituents,” such as pigments, integral water repellents and finely ground silica. For a material to qualify for inclusion in a concrete masonry product under this provision, the material:

- must have been previously established as suitable for use in the product, and

- must either conform to applicable ASTM standards or be shown, via test or experience, not to be detrimental to the durability of the units or other masonry materials.

Fire Resistance Ratings

For construction requiring a fire resistance rating, the use of recycled aggregates may impact the method used to determine the hourly rating, because concrete masonry fire resistance ratings vary with the aggregate type(s) used to manufacture the units. Concrete masonry fire ratings can be determined by: model building code prescriptive tables (ref. 21), a standard calculation method as provided in Section 721 of the International Building Code (IBC) (ref. 21) and the ACI/TMS 216 (ref. 22); testing in accordance with ASTM E 119, Standard Test Methods for Fire Tests of Building Construction and Materials (ref. 23); commercial listing services; and deemed-to comply assemblies included in some building codes. These tools also include ways to increase a wall system’s fire resistance rating through careful placement of additional materials.

Currently, the standard calculation procedure applies to the following aggregate types: expanded slag, pumice, expanded clay, expanded shale, expanded slate, limestone, cinders, aircooled slag, calcareous gravel, and siliceous gravel. When units are made with a combination of these aggregates, the fire rating is determined by interpolation (see ref. 23 for more detail). When aggregate types other than those listed above are used, the fire resistance rating is determined using a method other than the standard calculation procedure.

TEK 07-01D, Fire Resistance Rating of Concrete Masonry Assemblies (ref. 24) contains a detailed discussion of concrete masonry fire ratings. Additional considerations for recycled aggregates which are not listed in the standard calculation procedure are their stability, safety and load-carrying ability when subjected to fire.

LEED MATERIALS & RESOURCES CREDIT 4: RECYCLED CONTENT

By increasing the demand for products that incorporate recycled materials, the Recycled Content credits are intended to reduce the environmental and societal impacts associated with extracting and processing virgin materials.

LEED awards 1 point to projects that demonstrate that the total amount of a project’s recycled content exceeds 10% based on both weight and the total building product costs. An additional point is awarded if the recycled content reaches 20%. Also, if the recycled content reaches 30%, a third point can be earned as an Innovation & Design credit.

LEED refers to the International Organization for Standardization (ISO) for the definition of what constitutes recycled content, and for the basis of determining the percentage – i.e., weight (ref. 25). Recycled materials are those materials diverted from the solid waste stream, either during the manufacturing process (pre-consumer) or after their intended use (post-consumer). The recycled content for LEED credit is determined as the sum of all post-consumer recycled content plus one-half of the pre-consumer recycled content.

To claim this credit, the LEED NC Reference Guide suggests establishing a project goal for recycled content materials, and dentifying product suppliers who can achieve this goal. The following sections describe how concrete masonry and hardscape products can contribute to recycled content goals.

Pre-Consumer Recycled Content

Pre-consumer (post-industrial) content as defined by the LEED v2.2 reference manual is “material diverted from the waste stream during the manufacturing process. Excluded is reutilization of materials such as rework, regrind or scrap generated in a process and capable of being reclaimed within the same process that generated it (Source ISO 14021). Examples in the pre-consumer category include planer shavings, plytrim, sawdust, chips, bagasse, sunflower seed hulls, walnut shells, culls, trimmed materials, print overruns, over-issue publications, and obsolete inventories.” (refs. 4, 25) It is important for the producer to work with the material suppliers to determine which materials can be considered recycled and which cannot. It is important for the producer to have documentation from the material supplier stating that a material is considered recycled for the purposes of contributing to LEED certification.

Post-Consumer Recycled Content

Post-consumer recycled content is consumer waste that can no longer be used for its intended purpose. The official LEED definition of a post-consumer material is “material generated by households or by commercial, industrial and institutional facilities in their role as end users of the product which can no longer be used for its intended purpose. This includes returns of materials from the distribution chain (ref. 26). Examples of materials in this category include construction and demolition debris, materials collected through curbside and drop off recycling programs, broken pallets (if from a pallet refurbishing company, not a pallet-making company), discarded products (e.g. furniture, cabinetry and decking) and urban maintenance waste (leaves, grass clippings, tree trimmings, etc.) (refs. 4, 25).

As with pre-consumer materials, a producer should work with the material supplier to document that the materials being used are specifically documented as post-consumer recycled material for the purposes of contributing to LEED certification.

DETERMINING RECYCLED CONTENT

The LEED recycled content credit(s) is based on the recycled content percentages, based on the total value of all permanently installed materials on the project. Note that mechanical, electrical and plumbing components are excluded from this total, as are specialty items such as elevators. In determining the percentages of recycled content, the contribution from concrete masonry and hardscape products is added to the contribution from other building components.

The following sections describe the procedure for determining the recycled content of a particular product, then combining all such data to determine the overall recycled content percentage for the project. The percentages are based on both weight and cost, as described below.

For a Product

The producer is responsible for reporting the percentages of reconsumer and post-consumer recycled content for each product sold. If the producer supplies other products in addition to block such as reinforcement, mortar, etc., the producer should also document the recycled percentages in each of these products and report them to the contractor who purchased them.

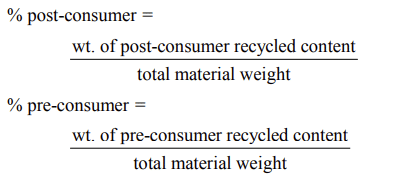

The percentages are based on weight, as follows:

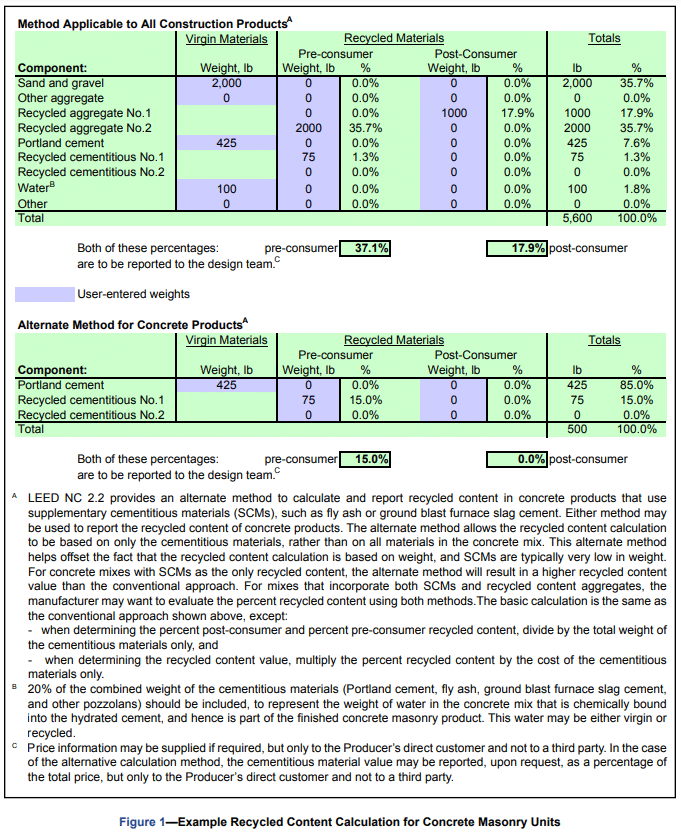

As an aid to the producer, CMHA has developed a simple spreadsheet to calculate these percentages (see Figure 1). Figure 1 illustrates the process of determining the weights of all constituent materials; determining the total weight; then determining the percent by weight of each recycled material. The total pre-consumer and post consumer percentages are simply the sum of the individual material percentages in each category.

Note that Figure 1 includes an alternate calculation, applicable to concrete products only. This alternate calculation is described below.

For a Product: Alternate Calculation per LEED for New Construction and Major Renovations

LEED for New Construction and Major Renovations, Version 2.2 and the LEED Reference Guide for Green Building Design and Construction, 2009 Edition (ref. 5, 26) provide an alternate method to calculate and report the recycled content for concrete products that use supplementary cementitious materials (SCMs), such as fly ash or ground blast furnace slag cement. This alternate method allows the recycled content calculation to be based on only the cementitious materials, rather than on all materials in the concrete mix. This alternate method helps offset the fact that the recycled content calculation is based on weight, and SCMs are typically very low in weight. For concrete mixes with SCMs as the only recycled content, this alternate method will result in a higher recycled content value than the conventional approach. For concrete mixes that incorporate both SCMs and other recycled materials, the manufacturer may want to evaluate the percent recycled content using both methods to determine which method yields the best result.

The basic calculation is the same as that described in the previous section, except:

- when determining the percent post-consumer and percent pre consumer recycled content, divide by the total weight of the cementitious materials only, and

- when determining the recycled content value, multiply the percent recycled content by the total value of the cementitious materials only.

Use of the alternative calculation method requires that the value of the cementitious materials be used in place of the total value of the product when the LEED project team determines the value of the recycled content. The producer would likely benefit from describing this value as a percentage of the value of the whole product and not as a monetary figure. When requested, the producer should report this value to the direct customer and not to a third party.

For the Project as a Whole

Based on information from the product suppliers, the design team determines the recycled content value for the project as a whole as follows:

- For each product, the percent recycled content is determined as the percent post-consumer (reported by the supplier) plus one-half of the percent pre-consumer. For the example in Figure 1, the percent recycled content for the concrete masonry units is 17.9% + 1/2(37.1%) = 36.5%

- For each product, the recycled content value is determined as the percent recycled content multiplied by the total product cost for the project. For the hypothetical project referenced in Figure 1, if the total cost of the concrete masonry units is $90,000, the recycled content value of the concrete masonry units is 0.365($90,000) = $32,805. It is important to note that the cost used in this calculation is the amount paid to the producer or the contractor for the product. It is not the cost of the individual materials that constitute the concrete masonry or hardscape product. The product cost should be supplied by the contractor. It is the contractor’s responsibility to separate their labor charges from the material charges.

- For the project as a whole, the recycled content percentage is determined as the sum of the recycled content values of each product, divided by the total cost of all of these products. If this total recycled content percentage is 10% or higher, the project earns one LEED point; if it is 20% or higher the project earns two LEED points. Projects with recycled content percentages of 30% or more may be eligible for an additional Innovation in Design point.

CONCRETE MASONRY UNITS RETURNED FROM A JOB SITE

Unused concrete masonry units returned to the manufacturer from a job site are considered under Materials and Resources Credit 2: Construction Waste Management. Under Credit 2, the building project with unused materials can earn LEED point(s) for returning those materials, and hence diverting them from a landfill. If subsequently used on another project, the recycled content of the units as manufactured is reported to the contractor or design team, as for unused concrete masonry products.

REFERENCES

- Standard Terminology for Sustainability Relative to the Performance of Buildings, ASTM E2114-06a. ASTM International, Inc., 2006.

- Concrete Masonry and Hardscape Products in LEED 2009, TEK 06-09C, Concrete Masonry & Hardscapes Association, 2009.

- Achieving LEED Credits with Segmental Concrete Pavement, PAV TEC-016-16, Concrete Masonry & Hardscapes Association, 2016.

- LEED for New Construction and Major Renovations, Version 2.2, 3rd ed. U. S. Green Building Council, 2005.

- LEED for Schools for New Construction and Major Renovations, Version 2007. U. S. Green Building Council, 2007.

- LEED for Retail: New Construction and Major Renovations, Version 3. U. S. Green Building Council, 2008.

- LEED Green Building Rating System for Core and Shell Development, Version 2.0. U. S. Green Building Council, 2006.

- LEED for Homes Rating System. U. S. Green Building Council, 2008.

- NAHB Model Green Home Building Guidelines. National Association of Home Builders, 2006.

- Standard Specification for Concrete Brick, ASTM C55-06e1. ASTM International, 2006.

- Standard Specification for Loadbearing Concrete Masonry Units, ASTM C90-06b. ASTM International, Inc., 2006.

- Standard Specification for Nonloadbearing Concrete Masonry Units, ASTM C129-06. ASTM International, 2006.

- Standard Specification for Prefaced Concrete and Calcium Silicate Masonry Units, ASTM C744-05. ASTM International, 2005.

- Standard Specification for Concrete Facing Brick, ASTM C1634-06. ASTM International, 2006.

- Standard Specification for Solid Concrete Interlocking Paving Units, ASTM C936-08. ASTM International, 2008.

- Standard Specification for Concrete Grid Paving Units, ASTM C1319-01(2006). ASTM International, 2006.

- Standard Specification for Dry-Cast Segmental Retaining Wall Units, ASTM C1372-04e2. ASTM International, 2002.

- Standard Specification for Concrete Masonry Units for Construction of Catch Basins and Manholes, ASTM C139-05. ASTM International, 2005.

- Standard Specification for Concrete Aggregates, ASTM C33-07. ASTM International, Inc., 2007.

- Standard Specification for Lightweight Aggregates for Concrete Masonry Units, C331-05. ASTM International, Inc., 2005.

- International Building Code, International Code Council. 2006 and 2009 editions.

- Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies, ACI 216.1-07/TMS 216-07. American Concrete Institute and The Masonry Society, 2007.

- Standard Test Methods for Fire Tests of Building Construction and Materials, ASTM E119-08a. ASTM International, Inc., 2008.

- Fire Resistance Rating of Concrete Masonry Assemblies, TEK 07-01D, Concrete Masonry & Hardscapes Association, 2018.

- Environmental Labels and Declarations – Self-Declared Environmental Claims (Type II Environmental Labeling), ISO 14021-1999. International Organization for Standardization, 1999.

- LEED Reference Guide for Green Building Design and Construction, 2009 Edition. U.S. Green Building Council, 2009.

- Standard Specification for Portland Cement, ASTM C150-07. ASTM International, 2007.

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. C618-08a. ASTM International, 2008.