INTRODUCTION

Prestressing is the general term used when a structural element is compressed prior to being subjected to building loads. This initial state of compression offsets tensile stresses from applied loads. Post-tensioning is a specific method of prestressing where tendons are stressed after the wall has been placed. The other type of prestressing, called pretensioning, involves tensioning the tendon prior to construction of the masonry. Because virtually all prestressed masonry built to date has been post-tensioned, the two terms are often used interchangeably as they apply to this form of masonry design and construction.

Post-tensioned concrete masonry walls have been built for schools, retail, manufacturing, highway sound barriers, warehouses and other types of structures. In addition, posttensioning has been used to strengthen and repair existing masonry walls. This TEK addresses new concrete masonry walls laid in running bond and built with unbonded vertical posttensioning tendons. Post-Tensioned Concrete Masonry Wall Design, TEK 14-20A (ref. 1) addresses the structural design of vertically post-tensioned walls.

POST-TENSIONING

In post-tensioned construction, hollow concrete masonry units are laid conventionally and prestressing tendons are either placed in the concrete masonry cells or in the cavity between multiple wythes. Current design codes (ref. 3) typically address post-tensioning of masonry walls laid in running bond. The cells or cavity containing the tendons may or may not be grouted. Grouting helps increase cross-sectional area for shear and compressive resistance, but increases construction cost and time.

Prestressing tendons are either installed during wall construction, or access ports are left in the walls so the tendons can be slipped in after the walls are completed. In either case, the tendons are tensioned only after the walls have cured for approximately three to seven days.

MATERIALS

Construction of a post-tensioned wall proceeds similarly to that of conventional masonry. The materials are the same, with the addition of hardware to develop the posttensioning forces, steel prestressing tendons which can be wires, bars or strands, and sometimes prestressing grout.

Concrete Masonry Units

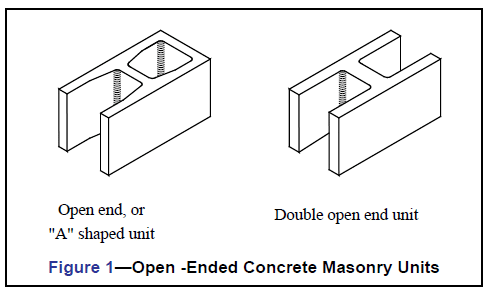

Open-ended (Aand H-shaped) concrete masonry units (Figure 1) are particularly suited to post-tensioned masonry, as these units can be placed around the tendons without having to lift the units over the tendons. While these two-core units are commonly used, proprietary units are also being developed that are specifically intended for use with tendons.

The net area strength of concrete masonry units must be at least 1,900 psi (13.1 MPa) per Standard Specification for Loadbearing Concrete Masonry Units (ref. 2). However, stronger units are often specified for post-tensioned walls to utilize the higher compressive strength.

Mortar and Grout

Type S mortar is commonly used for conventional loadbearing masonry, and Type S is a good choice for posttensioned masonry as well. Higher early strength mortars can accommodate earlier stressing.

Because mortar must be placed on concrete masonry webs adjacent to grouted cores to contain the fluid grout, full mortar bedding is sometimes specified when grout is used. Mortar bedding is a design issue as well, as the section properties of a wall with face shell mortar bedding are different from those of a fully bedded wall.

Because this TEK addresses unbonded tendons only, the grout discussed here is conventional grout (ASTM C 476, ref. 6), not prestressing grout. Prestressing grout is only used with bonded tendons. Encasing tendons in conventional grout restrains the tendons, but they are still considered unbonded.

Tendons

In the United States, tendons are usually high-strength bars joined by couplers, although Building Code Requirements for Masonry Structures (ref. 3) also allows steel strands or wires to be used. Couplers allow the use of shorter bars which minimizes the height of lifting. To date, there are no code provisions for tendons which are not steel.

Important features of the tendons are their size, strength, and relaxation characteristics. Most tendons currently available in the United States are bars between 7/16 and 1 in. (11 and 25 mm) in diameter, with strengths between 60,000 and 100,000 psi (413 and 690 MPa), depending on the supplier. Steel strand tendons are generally 270,000 psi (1,860 MPa). Tendons are usually placed in hollow cells of masonry units with little or no grouting, except for certain shear walls (these must be identified on the design drawings). In addition, the open-ended units shown in Figure 1 must be grouted to meet minimum web requirements in ASTM C 90 (ref. 2).

Tendon Corrosion Protection

Tendons must be protected from moisture deterioration, and the design documents should indicate the type of protection required. Tendons in walls with a likelihood of high moisture levels (single wythe exterior walls in areas of high humidity and interior walls around swimming pools, locker rooms, etc.) must have corrosion protection in addition to that provided by the masonry cover, such as hot-dipped galvanizing (ref. 3). In practice, most prestressing tendons are supplied with a hotdipped galvanized coating. It is considered good practice to use additional corrosion protection, such as flexible epoxy-type coatings, for tendons in moist environments.

Grouting

While the need for grouting is minimized compared to conventionally reinforced walls, grout is still needed for mild reinforcement, anchorages for the tendons, such as in bond beams, and tendon restraints.

Anchorages

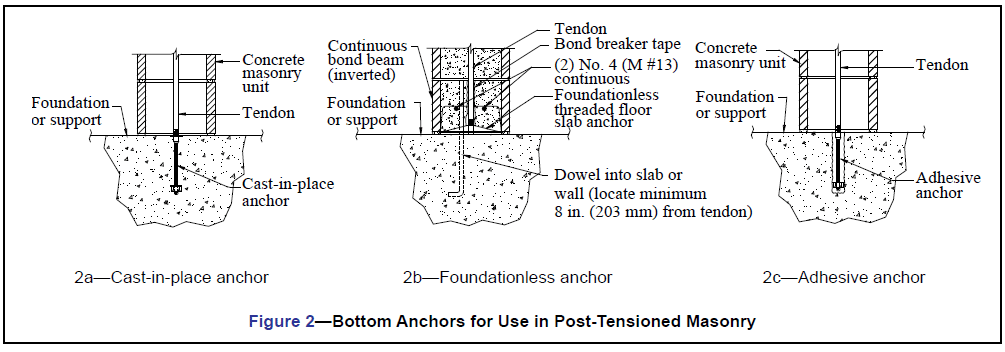

Each tendon is anchored at the foundation and extends to the top of the wall. Building Code Requirements for Masonry Structures (ref. 3) requires that tendons be anchored by mechanical embedments or bearing devices or by bond development in concrete. Tendons can not be anchored by bond development into the masonry. The foundation anchorage is embedded in the wall or footing while the top anchorage utilizes a special block, a precast concrete spreader beam or a grouted bond beam.

Unless the design documents call out specific bottom anchors, the contractor must select the anchor appropriate to the conditions. The cast-in-place bottom anchor (Figure 2a) is preferred for shear walls and for fire walls. While they are the best anchors for capacity, cast-in-place anchors are the most difficult to align. Cast-in-place anchors are often set by the foundation contractor, not the mason. Thus, quality control is a concern with these anchors.

The mason controls bottom anchor placement when either adhesive anchors are installed in the foundation (Figure 2c), or when an anchor is used which does not rely on the foundation for support (Figure 2b). If the anchor in Figure 2b is used, foundation dowels are grouted into the wall to lock it in place. In some instances, tendons can also begin at an upper floor and not at the foundation. In this case, the foundationless anchor is used with a bond beam, similar to Figure 2b.

The mechanical post-installed anchors can be used for nearly all applications, while the adhesive type should not be used for fire walls.

CONSTRUCTION

Key steps of post-tensioning concrete masonry walls include: selecting and setting the bottom anchorages; installing the tendons; selecting and setting the top anchorages; and a tensioning the tendons.

Bottom Anchors

Bottom anchors are most critical to the proper construction of post-tensioned walls. Alignment is essential to ensure that the tendons are placed exactly as intended.

Tendons

Tendons are usually placed concentric with the wall. However, they may be placed off-center to counteract bending moments due to eccentric vertical forces or lateral forces from a single direction. However, tendons should not be placed such that tensile stresses develop in the wall due to the combination of prestressing force and dead load.

Laterally-unrestrained tendons are free to move within the cell or cavity and are the simplest to construct. Laterally restrained tendons are not free to move within a cell or cavity. Restraint is accomplished by grouting the full height of the tendon or by providing intermittent restraints—either grout plugs or mechanical restraints—at the quarter points of the wall height.

Placing tendons is much like that of mild reinforcement. They may be installed after the masonry is constructed provided the design allows laterally-unrestrained tendons. If laterally restrained tendons are required, the tendon placement should proceed simultaneously with the masonry to allow the restraints to be installed unless the cells will be grouted.

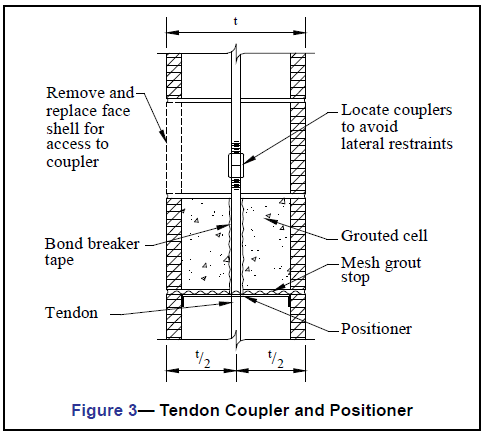

Tendon positioners (see Figure 3) are useful to maintain the tendon location within the wall during construction of the masonry. Positioners may also function as restraints if their capacity is determined by testing.

In all details, the tendons must be able to slip freely. If grout encases the tendon either totally or at restraints or bond beams, a bond breaker such as poly tape should be used to allow the tendon to slip.

Tendons can also be either bonded or unbonded. Bonded tendons are encapsulated by prestressing grout in a corrugated duct which is bonded to the surrounding masonry by grout. Both the prestressing grout inside the duct and the grout around the duct must be cured before the tendons are stressed. Thus, bonded tendons are also laterally-restrained. All other tendons are unbonded. However, unbonded tendons may be either laterally-restrained or unrestrained. Walls with laterally unrestrained and unbonded tendons do not require grouting and are generally the most economical to construct. However, the wall performance will not be as good as with laterally restrained tendons. The designer must specify which system will be used.

For some conditions, primarily seismic, grouted conventional reinforcement is used in addition to post-tensioning tendons to provide minimum requirements of bonded reinforcement. However, post-tensioned walls are most economical when the grouting is minimized or eliminated totally in comparison to a conventionally reinforced wall. The higher cost of the post-tensioning materials is more than offset by the savings of placing fewer tendons compared to reinforcing bars and eliminating most of the grouting.

Top Anchors

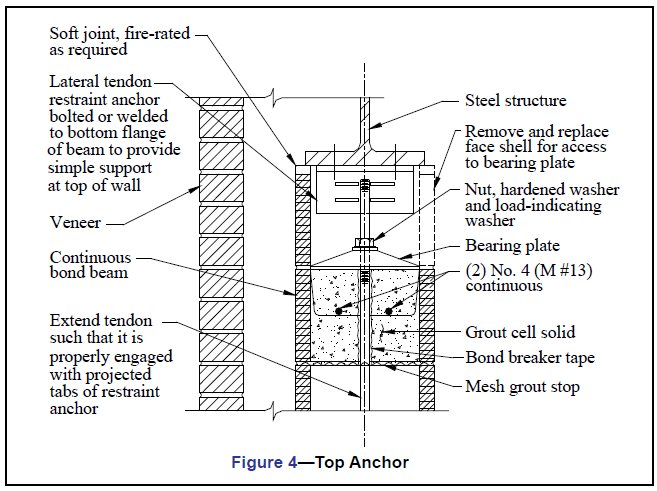

The top anchor must be placed on solid masonry, a grouted bond beam or a precast concrete unit. The anchor should not be supported by mortar.

Figure 4 shows a means for supporting the top of a wall when the top anchor is placed on a bond beam in a lower course. This detail can also be used for interior partitions.

Tensioning

At the time the tendons are stressed, the masonry is considered to have its initial strength (f ‘mi). The project specification should include either the minimum f ‘mi and minimum specified compressive strength of masonry ( f ‘m), or the amount of curing required before stressing can occur.

The sequence of tensioning, whether it is accomplished by fully stressing each tendon sequentially or by stressing the tendons in stages, is a function of the design specifications. Prestressed masonry design, and therefore the structural integrity of these walls, relies on an accurate measure of the prestress in the tendons. To ensure the required level of accuracy, Specification for Masonry Structures (ref. 4) requires that the following two methods be used to evaluate the tendon prestressing force:

1. measure the tendon elongation and compare it with required elongation based on average load-elongation curves for the prestressing tendons, and either:

2a. use a calibrated dynamometer to measure the jacking force on a calibrated gage, or

2b. for prestressing tendons using bars of less than 150 ksi (1,034 MPa) tensile strength, use load-indicating washers complying with Standard Specification for Compressible-Washer-Type Direct Tension Indicators for Use with Structural Fasteners, ASTM F 959 (ref. 5). If the two values determined by methods 1 and 2 are not within 7 percent of each other, the cause of the difference must be corrected.

QUALITY ASSURANCE

Post-tensioned walls must be constructed in conformance with masonry standards applicable to conventionally reinforced masonry. In addition to these, Specification for Masonry Structures (ref. 4) requires the following for posttensioned masonry:

- In the out-of-plane direction, the tolerance for the tendon placement shall be + 1/4 in. (6 mm) for masonry beams, columns, walls, and pilasters with cross-sectional dimensions less than 8 in. (203 mm). For cross-sectional dimensions greater than 8 in. (203 mm), the tolerance increases to + 3/8 in. (10 mm).

- In the in-plane direction, the tolerance for tendon placement is +1in. (25 mm).

- If tolerances exceed these amounts, the Architect/Engineer should evaluate the effect on the structure.

REFERENCES

- Post-Tensioned Concrete Masonry Wall Design, TEK 14-

20A. Concrete Masonry & Hardscapes Association, 2002. - Standard Specification for Loadbearing Concrete Masonry

Units, ASTM C 90-01a. ASTM International, 2001. - Building Code Requirements for Masonry Structures, ACI

530-02/ASCE 5-02/TMS 402-02. Reported by the Masonry

Standards Joint Committee, 2002. - Specification for Masonry Structures, ACI 530.1-02/ASCE

6-02/TMS 602-02. Reported by the Masonry Standards

Joint Committee, 2002. - Standard Specification for Compressible-Washer-

Type Direct Tension Indicators for Use with Structural

Fasteners, ASTM F 959-01a. ASTM International, 2001. - Standard Specification for Grout for Masonry, ASTM C

476-01. ASTM International, 2001.