Revised 2018

Interlocking concrete pavements are a flexible and durable system that performs successfully in the most demanding applications, conditions and climates. One of the most extreme conditions is the application of deicing chemicals to prevent or reduce ice buildup which can contribute to slips, falls and loss of vehicular control. This FAQ outlines factors that contribute to a low risk of damage from deicing materials on concrete pavers.

UNIT PROPERTIES IMPACTING PAVER DURABILITY

Ice that may form and expand inside the paver can cause stresses that may lead to degradation. Deicing materials mixed with the ice can increase the damage potential. Properly manufactured concrete pavers, however, are very durable and resistant to degradation because the high density of a paver limits deicing material from entering. In addition, a high cement content helps a paver resist damage from the stress of expanding ice. Research and experience have highlighted factors affecting the winter durability of concrete pavers, including the utilization of:

- Aggregates with low absorption that will not degrade when subject to freezing and thawing and deicing materials;

- Proper aggregate gradation that allows for high density when compacted during manufacturing;

- Sufficient cement paste to coat the aggregate and reduce capillary pores; and

- Sufficient compaction during manufacturing to ensure maximum density and uniformity.

Units manufactured with these characteristics typically yield a high density, low absorption, high compressive strength, resulting in a durable paver.

ASTM C936 Standard Specification for Solid Concrete Interlocking Paving Units includes freeze-thaw durability criteria for assessing the freeze-thaw durability and resistance to deicing salts. C936 references the test method ASTM C1645 Standard Test Method for Freeze-thaw and De-icing Salt Durability of Solid Concrete Interlocking Paving Units. C936 includes an optional lower freezing temperature for regions of the United States that experience severe freezing conditions based on a climatic zone map. The optional testing in 3% saline for these regions is equivalent to the testing required in the Canadian concrete paver standard, CSA A231.2 Precast Concrete Pavers. To obtain a copy of ASTM C936 or ASTM C1645 visit www.astm.org. The CSA standard is available from www.csagroup.org.

COMPARISON TO READY MIXED CONCRETE

Properly air-entrained and finished ready-mix concrete can resist freeze-thaw degradation, although over-finished, cast-inplace slabs or those made with re-tempered concrete with too much water can be susceptible to surface scaling. Compared to ready-mixed concrete, concrete pavers have the following advantages when exposed to freeze-thaw conditions and deicing agents:

- Stronger aggregate bonding from higher cement content than typically used in pavement quality ready-mix concrete;

- Smaller aggregates (more surface area for the cement to bond);

- Lower water/cement ratio as well as vibration and compaction during the manufacturing process to increase aggregate-cement contact and to eliminate the possibility of over-watering;

- Produced in a highly controlled manufacturing plants leading to lower variation in material properties with elimination of an over-finished surface; and

- Can be successfully installed in cold weather because they are properly cured before they leave the manufacturing plant.

Research prepared for the Utah Department of Transportation* in 2013 found that concrete exposed to sodium chloride experienced only minor, if any, adverse effects, while specimens exposed to calcium chloride, magnesium chloride, or calcium magnesium acetate (CMA) experienced significant deterioration, including scaling, cracking, mass loss, and compressive strength loss. While the literature review did not specifically address unit pavers, the findings are directly related to cured unit concrete properties. The report recommends that engineers responsible for winter maintenance of concrete pavements should utilize sodium chloride whenever possible, instead of calcium chloride, magnesium chloride, or CMA, and apply only the amount absolutely necessary to ensure safety of the traveling public. These findings support CMHA’s guidelines for deicing salt exposure. *Physical and Chemical effects of Deicers on Concrete Pavement: Literature Review, Report No. UT-13.09 Prepared for Utah Department of Transportation Research Division by Brigham Young University, July 2013

GUIDELINES FOR LIMITING DEICING CHEMICAL EXPOSURE

A key to successfully using deicing materials on unit concrete pavers is using only as much as needed to do the job. This will maximize their benefits while minimizing any damage to the concrete pavers and surrounding environment. The following guidelines can help limit the exposure of deicing chemicals while maintaining a safe environment:

- Rock salt (sodium chloride or NaCl) is the least damaging to concrete materials and should be used whenever possible.

- If a more effective, quicker acting deicer is necessary, consider the judicial use of calcium chloride.

- The use of magnesium chloride or CMA is not recommended because they can chemically degrade all types of concrete, significantly increasing potential damage. The potential for damage from CMA increases with the amount of magnesium in the formulation.

- Do not over apply deicing chemicals; follow the recommended dosage.

- Do not use deicing chemicals in place of snow removal but reserve them for melting ice formed by freezing precipitation or freezing snow melt.

- Once loosened, snow, ice and excess deicing salts should be promptly removed by plow or shovel to avoid a buildup in concentration of the deicing chemical(s).

- Protect vegetation and metal from contact with deicing chemicals as most can impair vegetation and corrode metals.

- Sand used in the winter for traction on permeable interlocking concrete pavements is not recommended. If used, sand must be removed with vacuuming in the spring to prevent a substantial decrease in surface infiltration.

- Using jointing aggregate is recommended as a better alternative to using sand when winter traction is needed on permeable interlocking concrete pavements. In addition, the aggregate can provide some refilling of the joints.

In addition, use CMHA-recommended jointing and bedding sand materials to minimize water penetration into the pavers. This can also help reduce salts from entering and accumulating in the jointing and bedding sand that may eventually degrade the pavers. CMHA also recommends adequate pavement slopes (typically a minimum of 2%) to facilitate surface water drainage and help remove deicing materials. While not essential, reduction of water entering jointing sand can be further enhanced with joint sand stabilization materials and/or sealers.

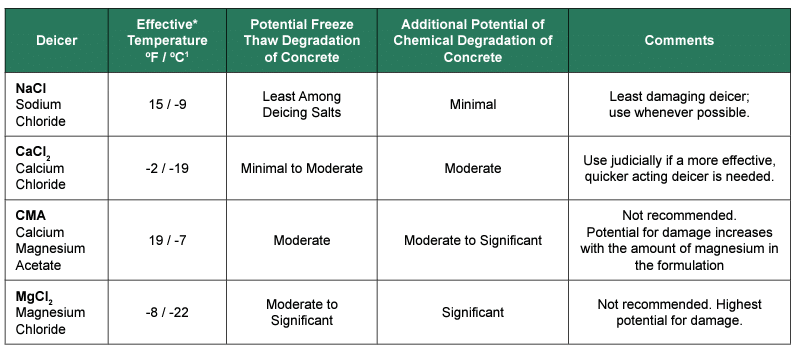

DEICING CHEMICAL COMPARISON CHART

The following chart compares common deicing chemicals with respect to their effective temperature, plus their impact on the potential freeze-thaw degradation and on chemical degradation of the concrete.

*Effective temperature is lowest practical temperature of the deicer defined as the lowest temperature at which the relative melting potential (MP) is 0.7 as calculated in reference 1 below.

* Information adapted from National Cooperative Highway Research Program Report 577 “Guidelines for the Selection of Snow and Ice Control Materials to Mitigate Environmental Impacts” ©2007 Transportation Research Board