One of the biggest perceptions about building with concrete masonry is its cost — that other common building materials like wood, steel, precast concrete or even insulated concrete form (ICF), is a more cost-effective option.

A study, however, dispels this belief and firmly labels it a misconception.

According to the report — which was prepared by Water G.M. Schneider III, Ph. D., P.E., an agricultural and biological engineering professor at Pennsylvania State University in State College, Pennsylvania — not only does concrete masonry compete with these other materials, it was the most cost-effective option or within five percent of the lowest cost system.

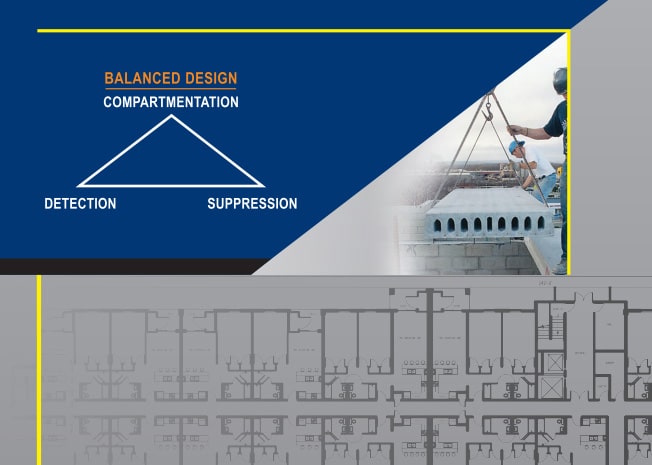

It also provided superior fire safety and protection, resistance to mold growth, potential to withstand damage from wind and weather, as well as reduced cleanup costs and quick reoccupation.

The overall goal of the study was to develop a construction cost model that accurately evaluates the relative construction expense of building multi-family structures. In order to carry out its aim, Schneider and those involved utilized unbiased data regarding the overall initial cost of construction, which ensured an accurate comparison between each system.

The building model chosen? A four story multi-family residential structure with 25,000 square feet of building area per floor. Each prototype was designed in accordance with the 2015 International Building Code and International Energy Conservation Code.

The systems that were studied were as follows and all possessed a precast concrete floor system: light gage steel framing, load-bearing concrete masonry, precast concrete walls, and insulated concrete form (ICF) walls. The sixth and final system had ICF walls with an ICF floor system.

The three locations selected for the study were Dallas, Texas; Edgewater, New Jersey; and Towson, Maryland. For both Edgewater and Towson, accepted federal prevailing wage was used for labor rates while in Dallas a compilation wage rate based on R.S. Means was evaluated. To track the changing costs of construction materials, costs were evaluated in each city during December 2016, May 2017 and September 2018.

In Edgewater, concrete masonry proved to be the most cost-effective system during all three study periods. During the December 2016 period, concrete masonry and wood frame construction were within one percent, while in the May and September 2017 period concrete masonry was two percent and five percent less expensive than wood construction, respectively.

In Towson, concrete masonry was the most cost-effective system in the May 2017 period, three percent below the cost of wood. In the December 2016 and September 2017, concrete masonry was five percent and two percent more expensive than wood construction, respectively.

In Dallas, concrete masonry was the most affordable option in the May 2017 trial, with an overall cost that was four percent less than wood frame construction. In December 2016, it was four percent more expensive than wood, while in September the margin was six percent.

Following publication of the initial study, additional cities have been evaluated for relative cost using the same methodology. Evaluations are currently available for:

- Phoenix and Tuscon, Arizona

- Los Angeles, Sacramento, and San Jose, California

- Washington, DC

- Atlanta and Savannah, Georgia

- Chicago, Illinois

- Des Moines, Iowa

- Kansas City, Kansas

- Baltimore, Maryland

- Waltham, Massachusetts

- Omaha, Nebraska

- Mineola and Syracuse, New York

- Charlotte and Raleigh, North Carolina

- Toledo, Ohio

- Toronto, Ontario, Canada

- Lehigh Valley, Philadelphia, and Pittsburgh, Pennsylvania

- Columbia, South Carolina

- Knoxville, Tennessee

- Houston, Texas

- Richmond, Virginia

To read the study in its entirety, as well as updates, click here.